NanoEnzo protects apartment building in Heemskerk against moisture with Nano-EcoLine Infusion

A large apartment building in Heemskerk had been struggling with moisture problems for a long time. With every rain shower, the porous facade absorbed too much water, which led to damage such as efflorescence and corrosion. NanoEnzo was called in to solve these problems.

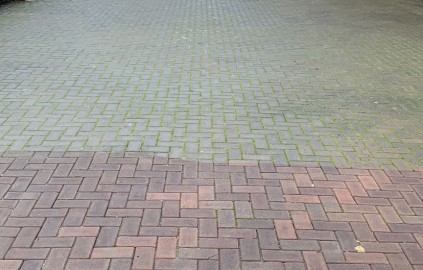

NanoEnzo used their innovative Nano-EcoLine Infusion, a special nano-impregnation coating that penetrates deep into the building material and forms a durable, water-repellent layer. Unlike traditional coatings, such as acrylic systems that block the pores, Nano-EcoLine Infusion preserves the breathability of the stone. This allows moisture to escape from the inside, while water from the outside is kept out.

After treatment with Nano-EcoLine Infusion, the facade remained dry during rain showers and further damage was prevented. The product is not only UV-resistant, but also protects against harmful substances such as chlorides and abrasive pollution. Nano-EcoLine Infusion offers long-term protection without changing the appearance of the building and is certified according to the strict EN 1504-2 standards.

Thanks to NanoEnzo's successful approach, the moisture problems of the apartment building in Heemskerk are now a thing of the past, with a future of sustainable protection.

Karsten Pipe Test: Determination of the Water Absorption Capacity of Brickwork

The Karsten Pipe test, also known as the Karsten method, is used to measure how much water a building material such as brickwork, concrete or plaster can absorb. This is especially useful after hydrophobizing (impregnating) surfaces, to check whether the treatment has been successful.

The test works as follows: a glass tube, the Karsten pipe, is attached to the test surface with adhesive clay and then filled with water to the zero level. The water level is checked after a certain time. If the masonry absorbs water, the level in the pipe will drop. The amount of drop indicates how much water the material absorbs and thus how effective the water-resistant treatment is.

Application of the Karsten pipe:

The pipe is filled with water and the drop in the water level is measured after 5, 10 and 15 minutes.

The difference in water level shows how much water has been absorbed in that period.

A successful hydrophobic treatment results in virtually no water absorption.

This method simulates water pressure comparable to strong winds (140 km/h), which helps to test the durability of the water barrier.