You currently do not have any products in your cart.

-

Sustainability & Environment

-

Environmental Innovation

-

Premium Quality – Made in Europe

-

Ultimate Protection & Care

-

Efficiency & Cost Savings

Nano EcoLine

Anti-slip coating - 5 kilo

Product number: NCN.AS.5L

Nano EcoLine Antislip WB is an ecological, water-based epoxy primer with a semi-gloss finish. This sustainable primer is solvent-free, odorless after curing and suitable for almost any surface, from concrete to wood and tiles. Thanks to the possibility of an anti-slip finish, it is ideal for safe applications in workshops, warehouses, cleanrooms and more. Easy to apply with a roller or spray, and perfect for those who choose quality and environmental awareness.

- Ecological & sustainable: Water-based and solvent-free, making it environmentally friendly and safe to use.

- Silk gloss finish: Provides a professional and aesthetic appearance on any surface.

- Versatile application: Adheres to concrete, wood, tiles, and more – ideal for various use cases.

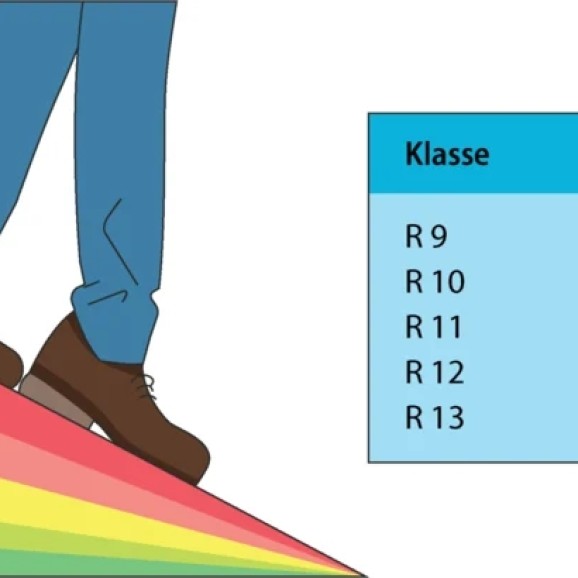

- Anti-slip option: Enhances safety in areas such as workshops, warehouses, and cleanrooms.

- Odourless after curing: Comfortable to use, even in indoor environments.

- Easy application: Can be applied with a roller or spray – no specialist required.

- Quality meets sustainability: Perfect for those who value high performance and environmental responsibility.

326,70

excl. vat

Out of stock